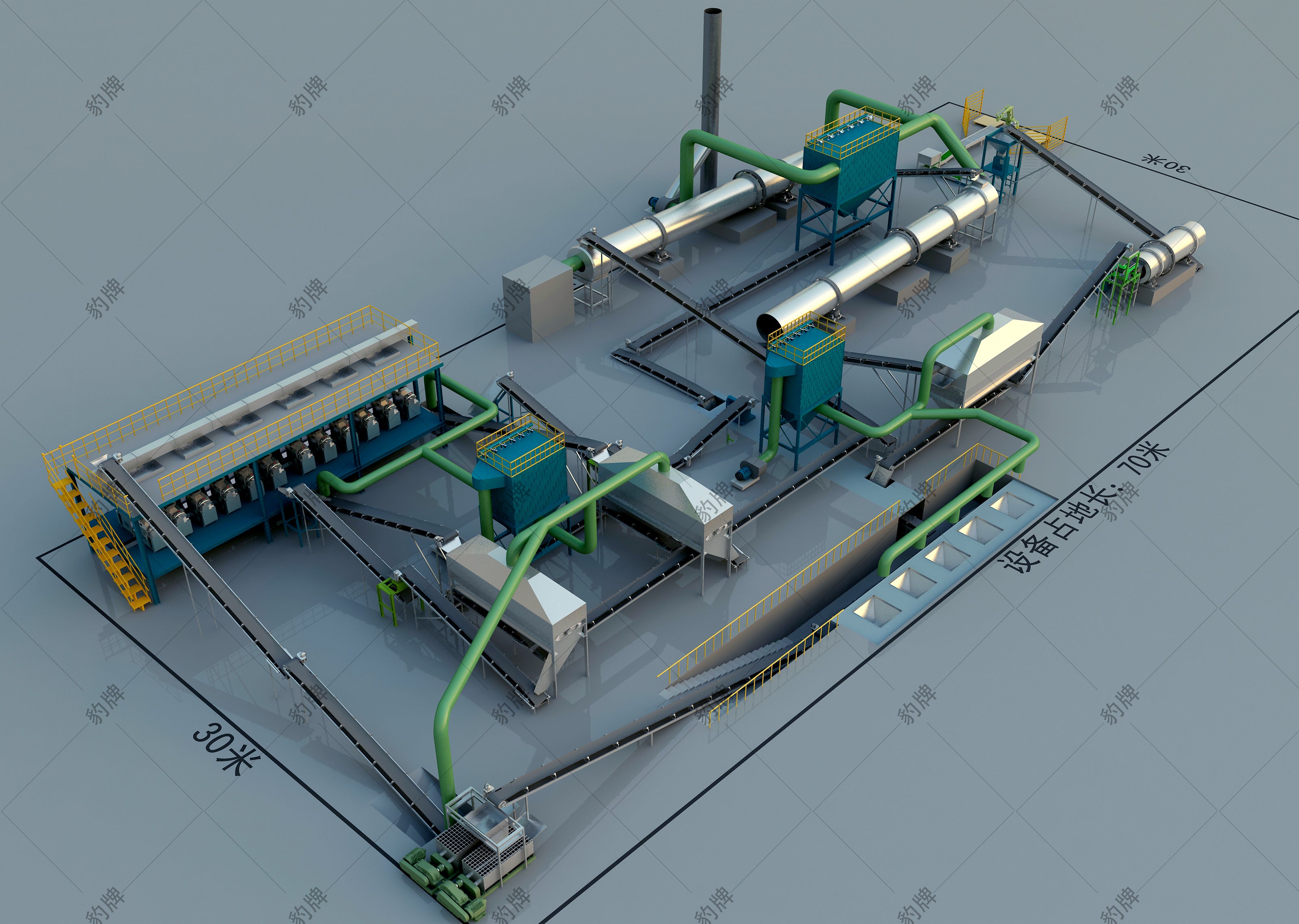

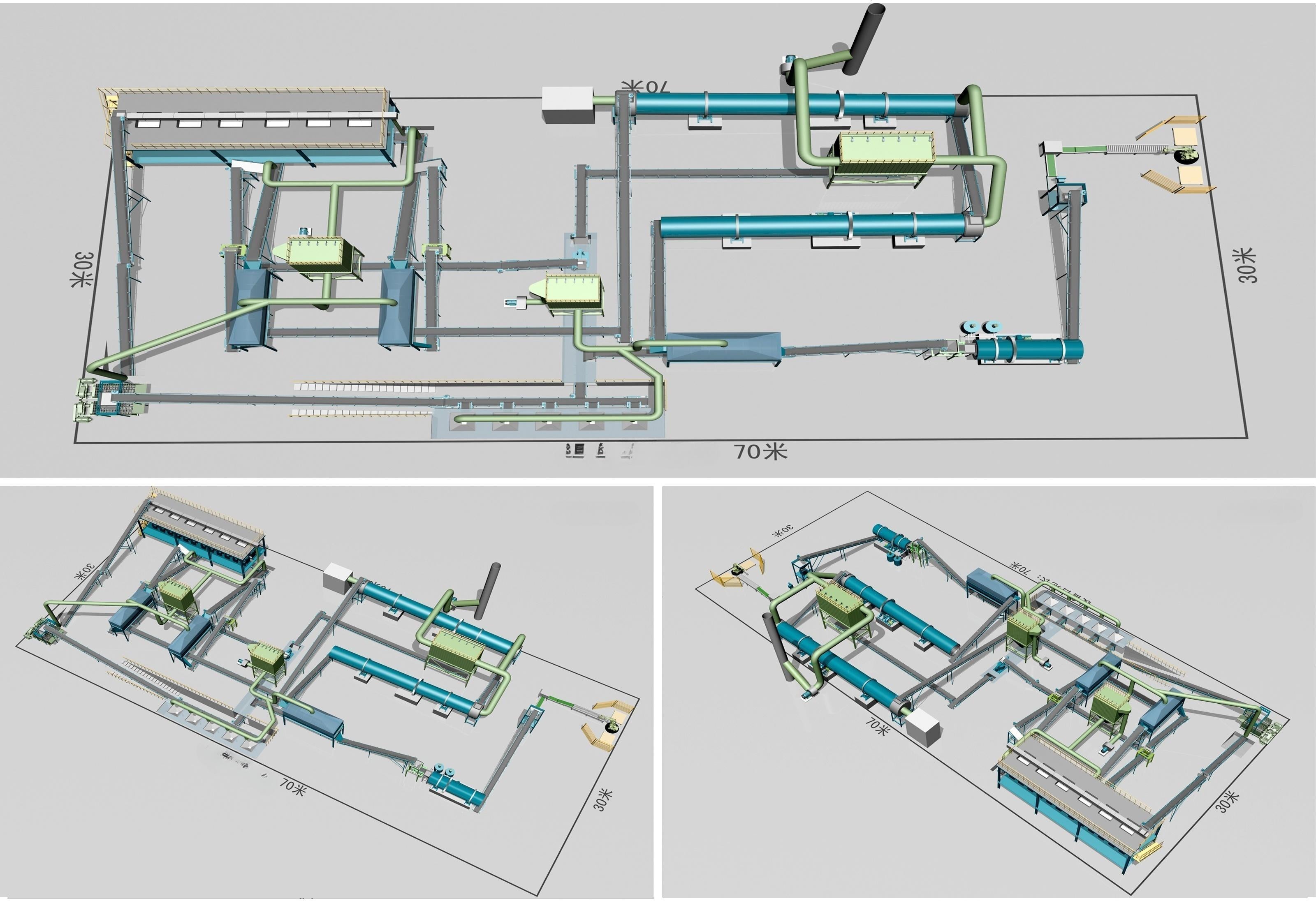

Product Introduction:

The double roller extrusion production line is a type of production line that uses a double roller extrusion granulator to press and shape materials. It is suitable for granulating a variety of raw materials, including compound fertilizers, organic fertilizers, chemicals, and feed. The main equipment of the double roller extrusion production line includes a horizontal mixer, chain crusher, double roller extrusion granulator, rotary screening machine, finished product silo, and electronic quantitative packaging scale. The working principle of the double roller extrusion production line involves first mixing the raw materials, then crushing and extruding them into shape, followed by screening and separating the finished granules, and finally packaging

Main equipment:

| Grinder | Mainly used to crush raw materials to meet granulation requirements. |

| Blender | Used for mixing and stirring materials, adjusting the moisture content of materials, and adding trace elements to meet the needs of granulation. |

| Double roller extrusion granulator | Used to make fertilizer granules. |

| Round polishing machine | This machine is mainly used in conjunction with a granulator to increase granulation output and achieve smooth and bright granules. |

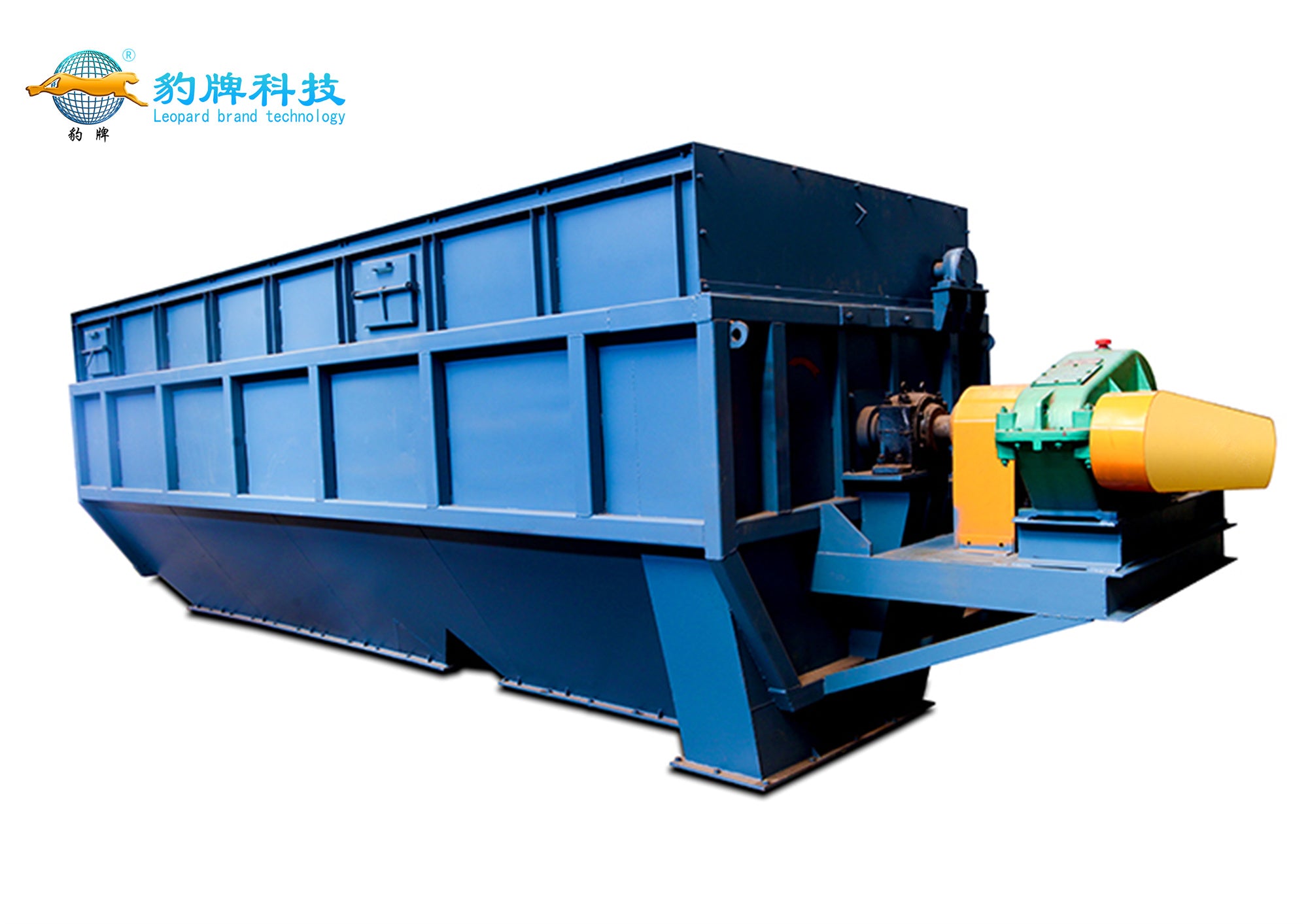

| Dryer | It is mainly used for drying after granulation, so that the moisture of the granules can be quickly reduced at high temperature, which is convenient for storage and realizes continuous and uninterrupted production. |

| Cooling machine | It is mainly used for cooling and dehumidification after drying, so that the material can quickly reach room temperature, meet storage requirements, and achieve continuous and uninterrupted production. |

| Screening Machine | It is mainly used for separation of finished products and returned materials, and can also realize the classification of finished products so that the finished products are evenly classified. |

| Packaging Machine | It is mainly composed of main machine, machine column, sewing machine head, conveyor belt, etc. It can be packaged in different specifications to improve work efficiency and reduce operating costs. |

Choose options